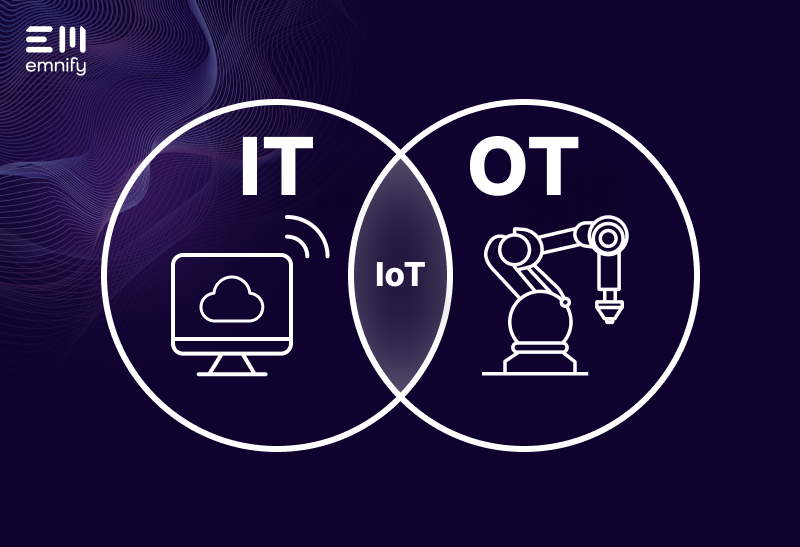

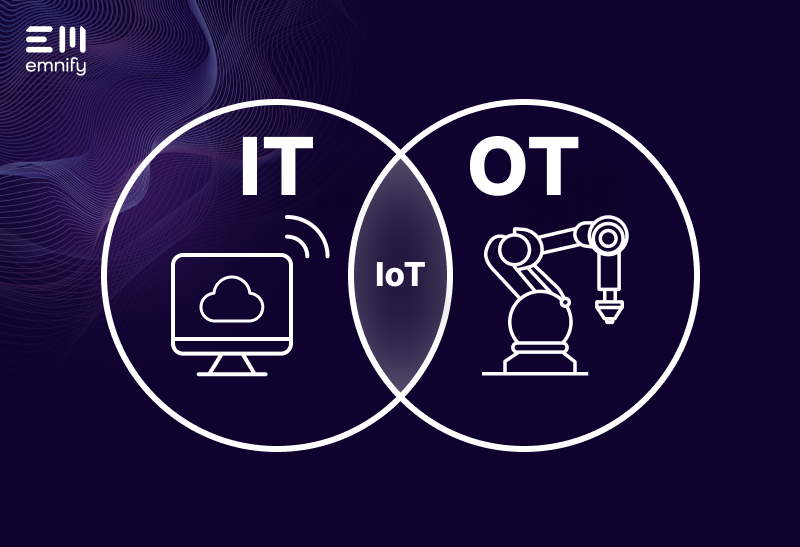

Quick Definition: Quick IT/OT convergence describes the merging of information technology (IT) and operational technology (OT). While these departments have traditionally been siloed, IT/OT convergence integrates the tools businesses use to collect data (IT) with the tools it uses to control processes (OT). It’s a critical component of Industry 4.0 that has improved manufacturing, healthcare, transportation, retail, and numerous other industries by allowing connected devices and real-time data to automate and inform operations.

In this article we will cover:

- Information technology (IT) vs. operational technology (OT)

- Benefits of IT/OT convergence

- IT/OT convergence challenges

- Examples of IT/OT convergence

- Continue exploring the future of IoT

The Internet of Things (IoT) is at the center of IT/OT convergence. Connected devices use sensors to collect real-time data from equipment, like resource consumption or output, temperature, speed, chemical composition, humidity, and errors. The devices then use actuators to control machinery and trigger actions based on changes in the information collected. Since the collected data has to be stored and distributed using IT resources directly impacting OT processes, these two distinct sectors are converging.

As businesses continue leveraging IoT to improve, simplify, and automate more operations, understanding the benefits of IT/OT convergence and the challenges it presents will only become more critical. In this guide, we’ll highlight these benefits and challenges as well as explore some real-world examples of how the IT/OT convergence is playing out in various industries. But first, let’s clarify what exactly is converging.

1) Information technology (IT) vs. operational technology (OT)

IT encompasses the technology, equipment, personnel, and resources businesses use to store and utilize data across the business, including servers, computers, applications, and IT professionals.

OT is the system businesses use to manage physical assets, including everything from manufacturing equipment and vehicles to boilers, freezers, HVAC systems, and specialized machinery. OT determines when and how these resources will be used.

Think of an organization like a brain. IT is the hippocampus, storing information from the body’s senses as memories, making them accessible later. OT is the motor cortex, which controls voluntary movement. In some ways, IT/OT convergence is like muscle memory: your brain can “automate” movement based on stored information about how to respond to particular stimuli.

Now let’s look at some of the key reasons IT/OT convergence is so valuable to modern organizations.

2) Benefits of IT/OT convergence

Bringing together information technology and operations technology empowers organizations to improve processes in various ways. Here are some of the key motivations for finding opportunities for IT/OT convergence.

2.1) Opportunities for automation

Relying on human operators creates bottlenecks. While OT personnel have the expertise and insights to make nuanced decisions about how to manage equipment and keep processes running smoothly, IT/OT convergence enables OT professionals to predetermine actions based on specific conditions, from scheduling maintenance based on a decline in performance to shutting down machinery due to a hazardous environment.

IoT sensors can transmit information to an application, which then passes instructions to an actuator based on that information, automatically controlling equipment without the need for a human operator. While OT employees still oversee and manage this automation, they no longer have to manually monitor every process and react to every situation.

Automation can reduce damage and costs associated with delays, allows OT departments to manage far more resources at once, and dramatically reduces costs associated with routine processes.

2.2) Better visibility into operations

When employees have to physically measure, observe, and/or record information before it can be acted upon, it can have devastating consequences. Suppose a valve is left open, and it takes hours for an employee to notice, or days for it to show up on a utility bill. You could have lethal levels of chemicals being released into the air, or flooding could destroy equipment and cause structural damage. (And again, this is where automation can save the day by shutting off valves and equipment as soon as the hazard is identified.)

Real-time visibility is crucial for operations technicians to react quickly to problems. It also enables organizations to react to issues before they cause harm. You establish thresholds that indicate equipment could be about to fail, or that something isn’t working as intended, and technicians can investigate and prevent larger issues.

Since IT/OT convergence allows businesses to constantly collect data, it also creates opportunities to recognize patterns and build a profile of what normal operations look like in a facility. For example, throughout the month, a factory will have certain days and times where it uses significantly more resources, or where particular equipment runs for longer periods. Understanding these usage patterns empowers OT employees to recognize anomalies faster.

Combining real-time visibility and a database of information over time, IT/OT convergence opens the door to predictive maintenance, where technicians use equipment’s current performance to plan and schedule maintenance, rather than scheduling maintenance at fixed intervals (preventative maintenance).

2.3) Lower costs

There are several ways that IT/OT convergence helps businesses lower costs. Through automation, businesses can reduce the amount of time technicians spend manually facilitating operations. This also ensures that the business can react to problems faster, before they waste more resources or cause more damage.

Since IT/OT convergence enables predictive maintenance, it can prevent unplanned downtime from disrupting daily operations. When equipment needs to be serviced, operations technicians can schedule and coordinate maintenance work and allocate backup equipment and resources as needed, rather than reacting in the moment to (sometimes literally) “put out the fire.”

And while preventative maintenance helps reduce unscheduled downtime as well, it creates a different problem: unnecessary downtime and wasted resources. Preventative maintenance schedules are based on a piece of equipment’s hours of operation or time since maintenance was last performed—not when parts are worn down, fluids are low, and the machine isn’t operating at peak performance.

These schedules are designed to prevent maintenance problems, but sometimes that means you’re spending time, money, and parts to “solve” a problem that isn’t there. Predictive maintenance uses measurable information to catch the earliest warning signs of a problem, so you’re not throwing out perfectly good parts or performing maintenance more often than you need to.

Between automating operations and enabling predictive maintenance, IT/OT convergence can yield considerable cost savings.

2.4) Potential for new services or pricing models

Depending on your business, IT/OT convergence could enable you to offer different pricing structures and services based on how your equipment is used, instead of requiring customers to purchase equipment outright, which may be excessive for their short-term needs or limited budget.

3) IT/OT convergence challenges

While IT/OT convergence has immense potential to improve business processes, there can be significant barriers to implementation. It may require restructuring the relationship between IT and OT, investing in new tools, or modernizing old ones. Let’s look at the main obstacles that inhibit IT/OT convergence.

3.1) Siloed processes and expertise

You can’t simply flip a switch and dissolve the traditional wall between IT and OT. Operations technicians need training in IT processes, and IT technicians need training in OT processes—so that each department understands how their decisions impact the other. And while IT and OT don’t necessarily need to share the same workspace and work together on everything, IT/OT convergence creates a significant enough overlap that will require them to consult one another more often.

For example, with IT/OT convergence, IoT security and IoT connectivity play pivotal roles in managing and controlling operations, but these are areas of responsibility that fall under IT. And since operations equipment is fixed with IoT sensors that collect and transmit data over a network, OT decisions could have serious implications for the IT department, and vice versa.

IT/OT convergence requires a shift in mindset and merging of these traditionally siloed processes. IT and OT professionals will need to trust and turn to each other’s expertise to create solutions that support operations without compromising security.

3.2) IoT security

Historically, IoT devices have been notoriously vulnerable to hacking. Some transmit unencrypted data, which can easily be intercepted and manipulated. They often have too little power to accommodate more advanced security features. They can be captured to use in botnets, which use DDoS attacks to bring down massive networks. And their proximity to valuable data and devices can make them a dangerous stepping stone to larger targets.

IT departments need to be intimately familiar with how each connected device fits into the business’ tech ecosystem and any threats it poses to the network. In some cases, this may mean that operations teams will have to compromise some of the functionality they want to go with a more secure solution, and they’ll always need IT to be involved in selecting converged technology.

3.3) Integration

IT/OT convergence works best when a facility’s connected devices integrate with the operations team’s tech stack. Otherwise, technicians have to constantly jump in and out of multiple portals and solutions, and some critical information is bound to fall through the cracks. You want the data they need to appear in the places they already spend their time—their ERP and other tools they use to manage and control operations. This often requires businesses to manually develop integrations, but many IoT businesses provide APIs and other solutions to help facilitate this process.

3.4) IoT connectivity

Every IoT device is built to operate on a particular connectivity solution, such as cellular, WiFi, Bluetooth, ethernet, or LoRaWAN. That means it’s also limited by the capabilities of this underlying technology. Some solutions, like WiFi, can only provide coverage in a very limited area, and don’t penetrate walls well or handle much interference.

But in an industrial environment where security is vital, the main concern is whether the network offers enough data throughput to facilitate firmware updates over the lifespan of the device. This is one of the areas where cellular IoT solutions like emnify excel, because cellular networks are highly versatile, are available nearly everywhere, and offer enough throughput to handle data intensive processes.

It’s also crucial that the network isn’t shared with other devices. Even if the IoT devices themselves are secure, other devices connected to the network could become a point of entry for a hacker, potentially compromising the IoT devices as well. Networks like WiFi and public LoRaWAN can be accessed by third parties, making them particularly vulnerable. This is another area where cellular IoT shines, as only devices with the right SIMs can access a cellular network, and then emnify helps you create a virtual private network (VPN).

4) Examples of IT/OT convergence

IT/OT convergence occurs in any business where IoT devices collect and transmit data that operations technicians use to manage equipment and processes. But what exactly that convergence looks like varies widely from one facility or business to another. It completely depends on what information the business can collect and what its daily operations look like. Here are some examples of how IT/OT convergence manifests in different industries.

4.1) Retail

Retailers have to manage massive amounts of information that’s constantly changing. And for more than 20 years, IoT has played a valuable role in retail operations, making this industry one of the earliest adopters of IT/OT convergence.

Connected devices transmit data about stock availability and expiration dates throughout the supply chain so operations teams can ensure each store has the inventory it needs. IoT sensors can also monitor the environments products are stored within, alerting employees when temperatures, light levels, and humidity fall too low or reach too high. IoT devices can even automatically adjust the environment to suit the product being stored there. This removes the possibility of human error and helps stores eliminate waste.

4.2) Manufacturing

Smart factories depend on IoT devices to monitor and transmit information about their manufacturing environment, equipment, and products, which either triggers actuators or alerts technicians to issues that need their attention. Manufacturing has been at the forefront of IT/OT convergence, leveraging automation to increase efficiency and production, decrease costs, and scale up their operations.

Perhaps one of the more interesting instances of IT/OT convergence in manufacturing are reconfigurable manufacturing systems and on-demand manufacturing, where manufacturing processes initiate and adapt in response to product orders. The factory changes its operations based on what needs to be manufactured—or even how an established product order has changed. It’s a monumental evolution in manufacturing that depends on this merge and synchronization between IT and OT processes and infrastructure.

4.3) Construction

A construction company may not have a formal IT department, but they depend on information systems to track assets and collect information about jobs, equipment, and personnel. This information feeds directly into daily operations, helping construction managers coordinate work across multiple sites and minimize unscheduled downtime for bulldozers, backhoes, cement mixers, forklifts, cherry pickers, and other critical assets. Companies can monitor where these assets are, when they were last serviced, how long they’ve been in operation, and what condition they’re in, then plan maintenance and work accordingly.

5) Continue exploring the future of IoT

IT/OT convergence is one of the many ways the Internet of Things is revolutionizing industries all around the world. Over the next few years, we will continue to see this sector take off in fascinating new directions as 5G, NB-IoT, and LTE-M become more accessible and enjoy wider adoption. And innovative new applications for connected devices are emerging all the time.

In The Future of IoT newsletter, we examine trends and newsworthy developments in the Internet of Things, helping you stay on top of what’s important now and where things are going in the years to come. Once a month, we’ll share our latest insights with you.

Get in touch with our IoT experts

Discover how emnify can help you grow your business and talk to one of our IoT consultants today!

.jpg)

Director of Customer Success at emnify, Jean-Eudes is an expert in IoT.