IoT in manufacturing - the product of the IoT and Industry 4.0

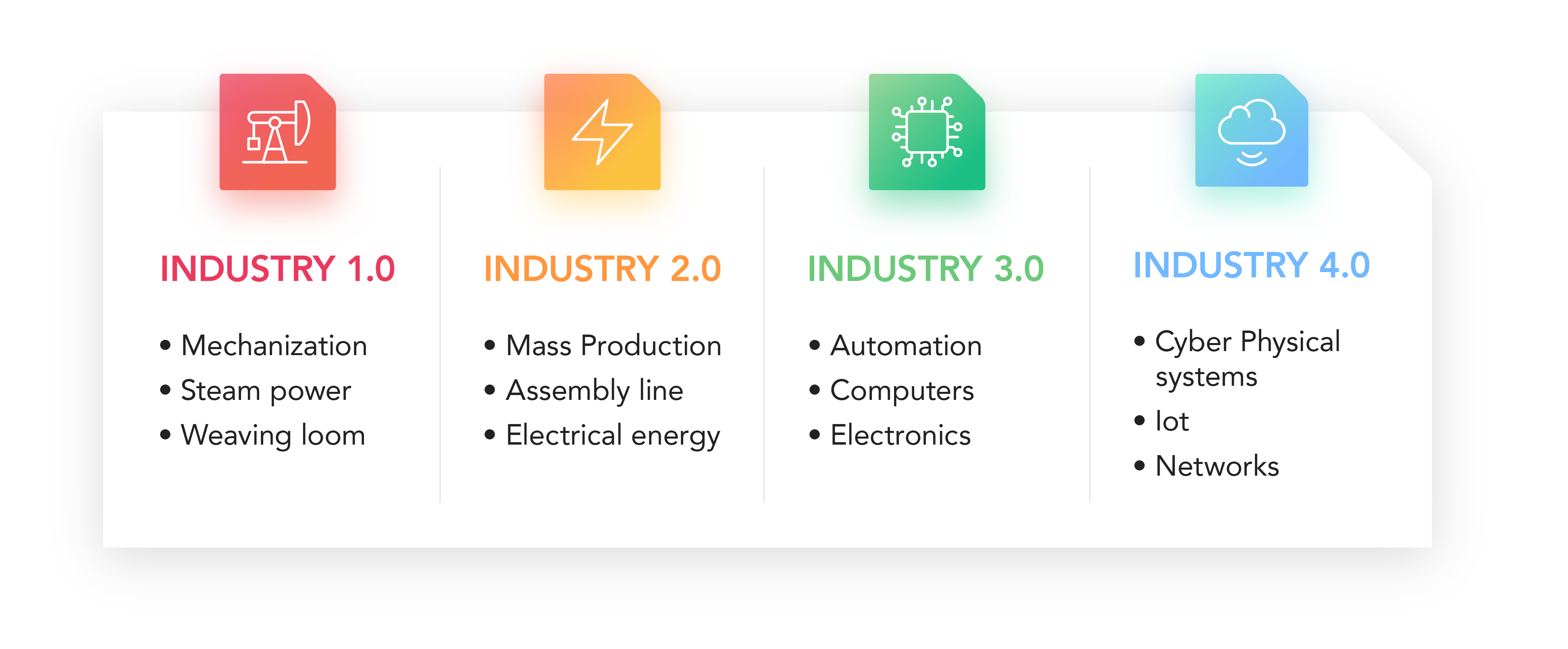

IoT in manufacturing is one of the most future-oriented technologies for the industry. It bundles together two digitization strategies – the Internet of Things and Industry 4.0. The product of these two technologies is the Industrial Internet of Things (I-IoT) – the IoT for industrial manufacturing. It combines machines that can learn with big data technologies, sensor technology and automation technology that already coexist in an industrial environment. The closer networking of the digital world of machines creates the potential for profound changes in global industry and many areas of private and social life.

In combination with modern mobile radio technology, the cellular IoT is created. The cellular IoT is particularly important when it comes to the global connectivity of end devices. As today’s connectivity for IoT devices becomes better and better, cellular networks can provide reliable and secure IoT services using existing network infrastructure.

Below, we demonstrate three smart ways to use cellular IoT in manufacturing (Previously, we considered five smart ways to use cellular IoT in logistics.)

1 – IoT manufacturing - limitless connectivity in robots

The company "Intelligent Marking" invented and developed the first autonomous line marking robot. One of the company’s biggest problems was installing the correct SIM cards in the marking robots before they were shipped all over the world. For the manufacturer, this has always required enormous effort. After all, there are different network providers in every country with different signal availability. In one country alone, there may be one region where provider A gives a stronger signal than provider B, yet in a neighboring region, provider B delivers the stronger signal. The company had to constantly evaluate which SIM card needed to be inserted in which robot for which country or region.

Today, Intelligent Marking uses emnify SIMs, which are network-agnostic, always selecting the network with the strongest signal. These SIM cards are now inserted in every single robot, no matter where it is sent.

2 – IoT manufacturing - predictive maintenance as a new maintenance method

Predictive maintenance is a sub-area of predictive analytics and is considered one of the most tangible applications of Industry 4.0 and thus the Internet of Things. This enables status data to be proactively maintained from machines and systems. Timely maintenance and repair, or proactive support for the replacement of parts, can reduce rejects in production, allow better maintenance service levels with customers and minimize service costs. As a basis for this, state models of machines and processes as well as historical and state data of the machines must be available. Using suitable algorithms from statistical learning, this mass data can provide valuable information regarding an assessment of the development of the parts.

A simple example of how predictive maintenance works can be explained using the plastics industry:

- The sensors used continuously examine the injection molding machines that produce the liquid plastic for wear.

- The plastic must be injected into the molds at a constant speed, otherwise no uniform filling can be guaranteed.

- The glass fiber particles in the plastic ensure abrasion as when this wear occurs, the injection molding machine turns faster so that a steady flow speed is obtainable. This causes excessive energy consumption.

- In this case, the energy data can be used to predict when a component should be replaced in order to make consumption more economical and thus prevent an impending failure.

By stepping into the Internet of Things, the user will be able to produce plastics economically and reliably. However, such a scenario is always limited to environments with a LAN or WLAN connection. If this scenario is expanded, the cellular IoT becomes very important. If, for example, the condition of a raw material extraction machine is to be monitored, a SIM card is essential. For example, when drilling for oil in the desert where there is no broadband connection, the drill head of the oil extraction machine can be monitored to ensure it is replaced before the wear becomes too intense and therefore breaks.

3 – IoT manufacturing with smart grids

A smart grid, also known as a smart power grid, refers to intelligent distribution grids for power supply that adapts to the supply of energy feed-in and consumption using the IoT. These energy networks include needs-based and efficient energy distribution of central and decentral fed energy and the control of consumption behavior. These are nationwide and cross-border electricity grids that receive their energy from base load plants, hydroelectric power plants, regenerative energies and thus control the consumption of such energy as required.

During the next phase, the energy distributions cannot only be broken down to separate plants, but also to individual machines. The cellular IoT makes it possible to monitor network-connected machines and plants, and mobile devices and mobile machines with a mobile network connection. This simply means that smart grids are distributed much more granularly throughout the world and are well received everywhere.

Cellular IoT in manufacturing brings innovative use cases

The cellular IoT, and the digitalization in production because of it, brings numerous new application scenarios. The new technological possibilities give rise to opportunities and potential for industry that nobody could have predicted. New application scenarios within companies are a significant factor that is certainly changing. Cellular IoT can make a difference in the medium term, as connectivity is one of the most important factors in building a functioning IoT. Even today, there are large regions where network connectivity cannot be achieved with obtainable resources. With the right cellular IoT SIM cards, this problem is almost eliminated and a network availability of almost 100% is achievable.

These examples only explore a fraction of the possibilities that actually exist. If you are inspired by the above five smart ways, and interested in learning more about what cellular IoT connectivity could bring to your business, then chat to one of our experts via the chat box in the bottom right corner of this page.

Get in touch with our IoT experts

Discover how emnify can help you grow your business and talk to one of our IoT consultants today!

.png)

Kalliopi Papanikolaou

Kalliopi is a CS Manager, highly motivated at integrating different solutions and helping customers enable and facilitate their daily business.